Professional Floor Leveling

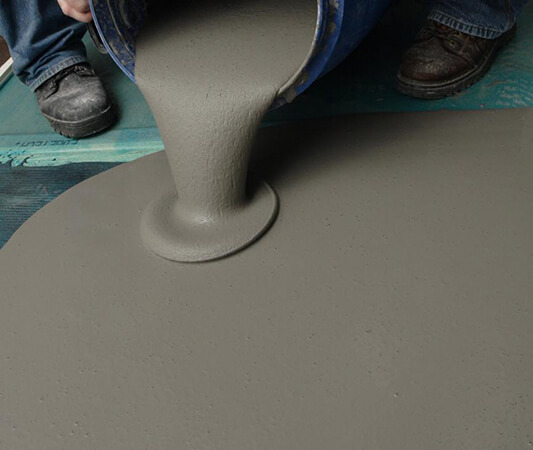

MaConcrete Floors can make your floor level enough for any purpose, whether it's tile or linoleum installation or polishing and staining the floor to a high sheen.

Here's how the process works: Any high spot 1/8" or higher will require grinding to level the floor. The contractor will systematically check the floor in every direction to identify these high spots.

Then the proper type of grinder will be chosen, whether it's a hand-held models or a larger machines that resembles a floor buffer.

Grinders use diamond tipped or diamond embedded wheels or pads to remove excess cement. A professional will know exactly how much to grind. Beware: Inexperienced amateurs will often over-grind and ruin your cement floor.

We offer a turnkey polished concrete process. We use the ULTRAFLOR ARDEX DIAMATIC Polished Concrete System. The ULTRAFLOR System is the only comprehensive polished concrete system with a detailed written process specifications for all aspects of the installation. We can ensure you a successful installation of your polished concrete floors, acid stained concrete floors and dyed concrete floors done.

Polish Concrete Floor is successively honed and polished with finer grits of resin bonds. The purpose here is two fold. The finish gets tighter and smoother which means that the floor surface gets easier to clean. Secondly, the floor will become reflective as it is honed with higher less aggressive grits. A note of caution - some contractors may do the metal bond diamonds and then densify the floor; and they will call this a polished floor. This is incorrect. While there may sometimes be a place for this system, it is generally agreed that at least 2 resin bond diamonds must be run on the concrete before one can call it a polished finish.

It also should be clarified that the least expensive part of the process is the polishing process, however it is this last stage or step that provides the aesthetics.

To help you the client understand the polishing process it is best to explain the resin bond diamond grits. After densifying we generally run the following grits….100/200/400/800/1800. See the explanations below as they relate to gloss.

- Level 0/Very Low gloss - stop at 200 grit resin bond diamond

- Level 1/Low gloss - stop at 400 grit resin bond diamond

- Level 2/Medium gloss - stop at 800 grit resin bond diamond

- Level 3/High gloss - stop at 1800 grit resin bond diamond

The client must decide how much shine they want and what is safe for their environment. The higher the grit/the higher the shine; the lower the coefficient of friction. Generally speaking polished floors are not slippery (even with water). Our level 1 and level 2 sheen finish is comparable to a brand new floor. Housekeeping and the removal of surface dirt is required to maximize the coefficient of friction.

It should also be noted that all concrete floors are not created equally; and hence they do not all polish the same.

Floor Leveling

These have a 4 to 6 inch disc and the speed is the fastest you need to use for safety reasons. Most common discs for this grinder are masonry discs; these are of composite material such as carbide, granite with fiberglass binding. These wear semi fast. This is the most versatile of the group, you can grind all masonry surfaces and it's very soft if you add no pressure or if you push on in it becomes more aggressive. You're able to get into tighter areas to grind plus it can be used flat or held at an angle. This grinder can be fit for a diamond wheel as well. Cutting wheels are very thin and can only be used on the edge not in the flat position. This grinder spins very fast. The next wheel that can go on this is the planer; this wheel is made of the same material as the cutting wheel, diamonds. This wheel is made to use in the flat position only. This is the most aggressive tool. For a journeyman concrete finisher this is a tool that can be perfected and can do beautiful work out of ugly concrete. This is the machine and wheel you would use on a floor if you had a crack and it began to lift apart till one side was higher, the diamond wheel would make short work out of it and level so you could never tell the slab rose up.